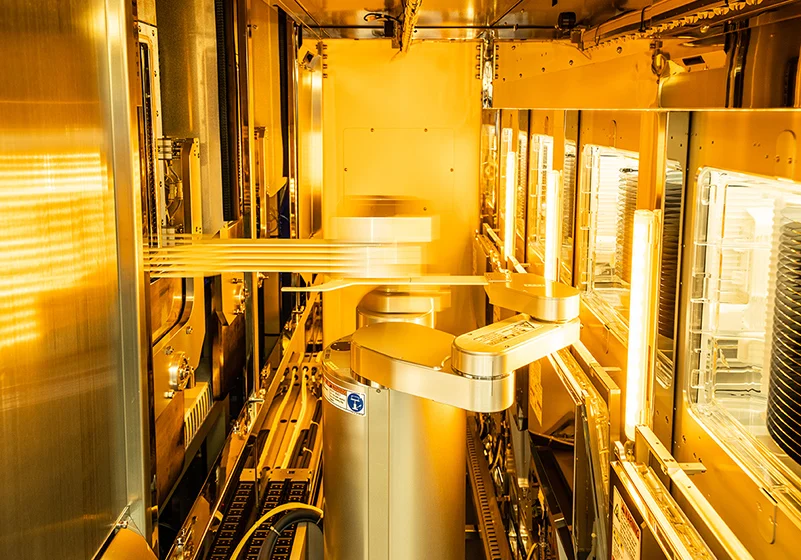

In the field of high current ion implantation, ultra low energy (ULE) is the ultimate challenge in terms of controlling manufacturing processes. Integrating domestic R&D and supply chains, AIBT has partnered with world-leading clients to overcome the technical challenges of cutting-edge logic processes.

AIBT has been spending more than two decades developing advanced technologies in ion implantation equipment, as it is crucial in the front-end manufacturing process of semiconductors. This has allowed AIBT to become Taiwan’s sole equipment manufacturer of equipment related to the core manufacturing processes of semiconductors, elevating the company to the ranks of major global equipment suppliers.

7F., No.18, Puding Rd., East Dist., Hsinchu City 300047, Taiwan

Tel:+886-3-577-2345

Fax:+886-3-579-7755

Email:[email protected]